DTF printing stands for Direct-to-Film printing. It is a relatively new technique in garment printing where designs are printed onto a special film and then transferred to fabric using heat and adhesive powder. It offers a vibrant, durable alternative to traditional printing methods like screen printing or direct-to-garment (DTG) printing.

How DTF Printing Works:

- Design Creation: A design is created digitally (often using software like Photoshop, Illustrator or Canva).

- Film Printing: The design is printed onto a PET (polyethylene terephthalate) film using a printer equipped with specialized DTF inks (typically, CMYK + white).

- Powder Coating: While the ink is still wet, an adhesive powder is applied to the printed film.

- Curing: The film and adhesive powder are heat-cured to partially set the adhesive.

- Heat Transfer: The film is placed on the fabric and heat-pressed, bonding the design to the fabric.

- Peeling: Once cooled, the PET film is peeled away, leaving the design adhered to the garment.

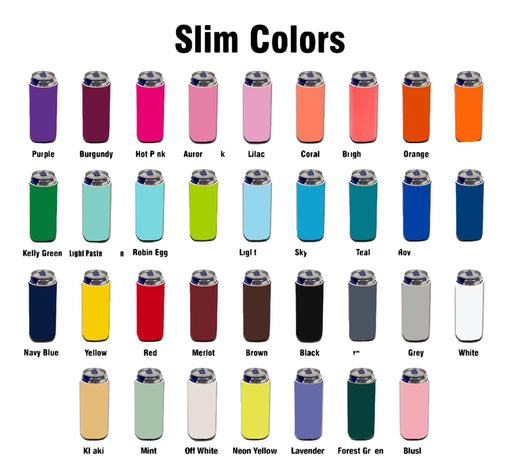

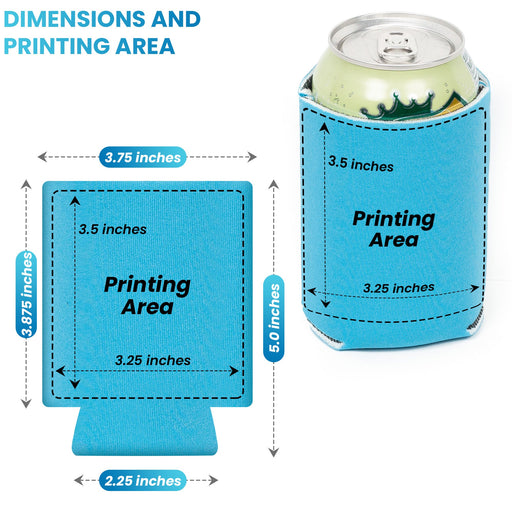

- QualityPerfection print custom koozies© on premium 4mm thick neoprene, only can cooler sleeves with this high quality fabric - contact us at contact@quality-perfection.com

Advantages of DTF Printing:

- Works on various fabrics: Cotton, polyester, blends, leather, and more.

- No fabric pre-treatment required (unlike DTG).

- Vibrant colors and fine details.

- Good durability and wash resistance.

- Allows small batch or on-demand printing.

Drawbacks:

- Requires special equipment and materials (DTF printers, films, and powders).

- Learning curve: Managing the heat, pressure, and curing process.

- Can produce slightly thicker prints due to the adhesive layer.

DTF printing has gained popularity for customizing apparel, including T-shirts, hoodies, hats, and more. It’s especially favored by small businesses for its versatility and ability to print complex designs quickly and cost-effectively.

Leave a comment